NeoDen Tech had developed a new PNP model- NeoDen4(TM4120V) with camera,which can help ensure the

mounting accuracy.

NeoDen4 pick and place machine is our newest & most advanced model till now.

Parameters:

Number of Heads with Vision enabled: 4

Placement Rate:10000CPH (vision off), 5000CPH (vision on)

Feeder Capacity:Tape Reel Feeders:48

Tape width: 8mm, 12mm, 16mm,24mm

Vibration Feeders: 5

IC Tray Capacity: 5

Component sizes with vision:Smallest Component size:0201 Largest Component size:TQFP240

Applicable Components: 0201,BGA,SOIC,SSOP,QFN,TQFP,Led Component,Diode,Triode,Tack Switch

Component Height Maximum:5mm

Resolution X/Y axis:0.01mm Z axis:0.1mm

Rotation:+/-180(360)

Positioning Accuracy:+/-0.02mm

X-Y repeatability:+/-0.02mm

Applicable PCB area:310mm*1500mm

Placement Area:310*1500mm(without waffle Tray) 140*1500mm(With 1 waffle Tray)

Programming:SOFTWARE AUTOMATIC PROGRAMMING/MANUAL MECHANICAL PROGRAMMING

Main Control:GUI

Power Supply:220V, 50Hz (convertible to 110V)

Power:180W

External Dimensions:Machine:87*68*48CM

Packing size:94*74*60CM

Net Weight:60KGS

Gross weight:80Kgs

Main Features

1. Dual vision system (up-looking and down-looking camers), identify and calibrate the different components at one

time, improves the accuracy of placement from 0201 to BGA;

2. Auto rails, help to achieve continuous placement and solve the problem of long LED bar, ex. 1.2m LED strip;

3. Automatic electric feeders, reduce the feeding deviation;

4. General conveyor is supported, so a SMT production line can be setup, which is more time-saving and labor-saving

5. Four placement heads can pick up and calibrate components at one time.

6. The device supports remote system upgrade, NeoDen provides a life long system upgrade service for free to you;

Certifications:

Established in 2010, NeoDen Technology Co.,Ltd., is a high-tech corporation located in Hangzhou, China. Our primary products are desktop automatic pick and place machines. In China, we are the leader in this technology with CE and more than 30 patents registered.

Detail Images:

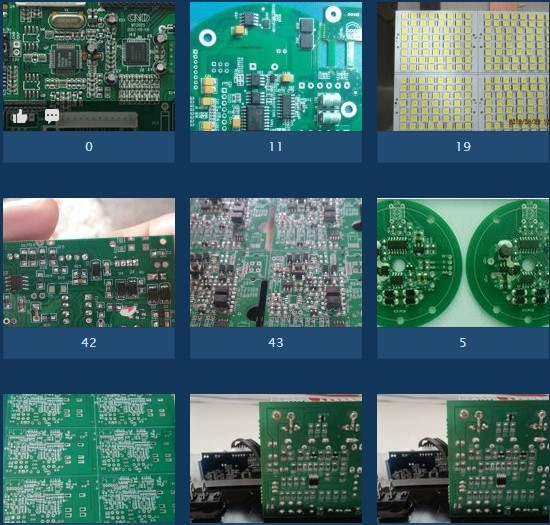

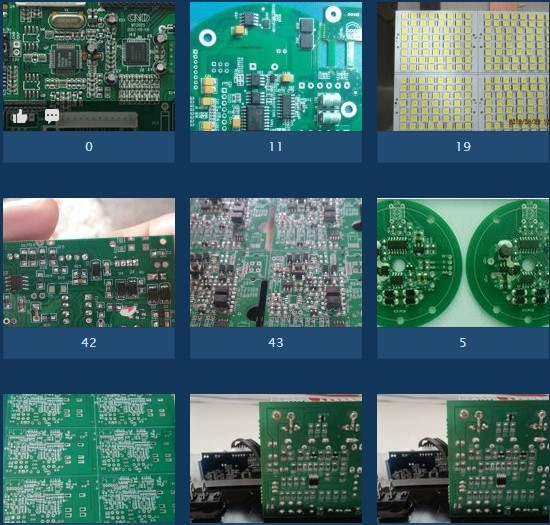

Mounting Effect:

Mounting Effect:

Why Choose NeoDen:

Why Choose NeoDen:

1.Light weight body,occupy small area

2.User friendly interface,no need professional SMT engineer,entry-level device

3.High integrated,no need extra pump or any supporting facility

4.High accuracy and reliability,make up the defection of manual work

5.Low cost,reduce expense to own a professional automatic SMT production line

6.International express with door to door service,3-5 working days delivery

7.Especial for laboratory research and development,samples,to avoid any patents and designs revealment

Video:

https://www.youtube.com/channel/UCe5FjacDVT42MxKF2Q6Z9OQ/videos?view=0&sort=dd&shelf_id=0

Our Service:

Factory Overview:

Factory Overview:

Accessories:

Accessories:

1) Pick and Place Machine NeoDen4: 1

2) Nozzle: Totally 10 (XN07=3,XN14=3,XN40=2,XN22=2)

3) 8G Flash Drive: 1

4) Power Cord(5M): 1

5) Video training course: 1

6) Double Sided Adhesive Tape: 2

7)Allen wrench Set:5

8)Tool Box:1

9)Reel holder stand:1

10)Vibration Feeder:1

11)Rail Extension Parts:4

12)User Manual:1

Packing:

Warranty:

Warranty:

The complete machine has a warranty period of

TWO year from the time of purchase and lifelong service support as well as a long-term factory price supply. We provide online Q/A and trouble shooting support and technical advice service.

Thank you very much for your support on Neoden Tech's machines.

Email:Tonny @ neodentech.com Skype:tonny-neoden